The Client:

A provider of powder coating and painting services for the automotive industry.

The Challenge:

This shop was using cellulose blended – 80/20 filters in their dust collection system. These filters would overload quickly, leading to dust entrainment and premature cartridge filter failure which required frequent filter changeouts.

The Solution:

Fab-Tex suggested that the client replace their overworked paper blend filters with Spunbonded Polyester cartridge filters. Polyester filter media has a much higher air-to-cloth ratio than 80/20 cellulose blend media. Because polyester filters require fewer pleats per square inch, the result is a filter with much more open pleat spacing compared to their current paper filters. This will allow much better dust expulsion and release qualities. This design and construction improvement ensures more durable and easy-to-clean filters, overall offering an improved and more effective filtration system.

The Outcome:

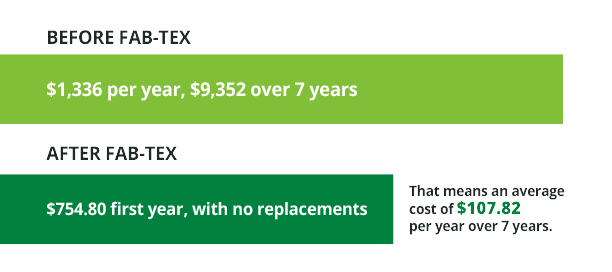

The client received their initial supply of 8 Spunbonded Polyester cartridge filters and installed them right away. Where they were once replacing filters every 6-9 months, they now have a filtration system running for 7 years – and counting! – without needing a single filter changeout.

Total savings of $8,597.20, or 92% of total filter costs over 7 years!

Key Takeaways:

Cheaper filters with higher media square footage and pleat counts don’t promise a cheaper outcome. Having to replace your filters more frequently is more costly than investing in better quality filters that will last longer and stand up to rigorous use. There are always many aspects of filtration that must be considered when replacing filters.

“The filters you recommended were excellent – a game changer for my situation.”