The food industry faces ongoing challenges in managing food processing hygienically while remaining efficient. That’s where Fab-Tex air filters come in. Industrial filters from Fab-Tex provide support throughout the process by:

The food industry faces ongoing challenges in managing food processing hygienically while remaining efficient. That’s where Fab-Tex air filters come in. Industrial filters from Fab-Tex provide support throughout the process by:

- helping to improve indoor air quality

- helping prevent potential contamination risks associated with working with fine powdered materials

- increasing the ability to recover clean powder in reclaim applications

- reducing overall emissions levels

Fab-Tex specializes in manufacturing filters that meet the specific requirements of food industry applications.

Air Filtration for Critical Food Applications

Air filtration is necessary to maintain product quality across critical food applications. Keeping spores, mold, viruses, bacteria, and other contaminants out of the airstream is critical. Fab-Tex manufactures safe and cost-effective air filters that utilize our varied selection of filtration medias available and by suggesting specifications that will optimize your dust collection system. Our expertise lies in designing filters that ensure the right efficiency and micron size media is used for the particular dust characteristics unique to each application.

Talk to a Fab-Tex Expert about upgrading the air filters in your food processing facility

High-Efficiency Air Filtration Across Low-Care, High-Care, and High-Hygiene Areas

Different areas in the food processing industry have distinct filtration and hygiene needs. Properly tending to these needs has a measurable impact on the final product quality. Air filtration and dust collection systems are installed in facilities to comply with tough food hygiene and safety regulations.

Low-Care Areas

Low-care areas are designated for activities other than production and product handling. Such places include dry food storage and are categorized as low-level-hygiene zones. They have basic hygiene requirements like cleanliness to guard against product contamination.

High-Care Areas

In high-care areas, contamination needs to be kept to an absolute minimum. These areas require high airflow and positive pressure environments. They include intermediate food processing steps such as produce washing and processing and ingredient preparation.

High-Hygiene Areas

products in high-hygiene areas require strict air quality control. Areas like food production, processing, cooking, and packaging all require special attention to filtration methods to eliminate all potential sources of contamination.

Ensure the highest food handling standards in low-care areas, high-care areas, and high-hygiene areas with dedicated filters. Custom air filters for food processing eliminate harmful particles like airborne pathogens, mold, fine dust, viruses, and volatile organic compounds (VOCs), preventing microbiological cross contamination. Clean air and high indoor air quality are crucial for successful food production. Failure to comply with these standards not only affects the overall brand but also risks the health of consumers. Don’t compromise on food quality and safety.

Explore Food-Grade Fab-Tex Filters, Media, and Equipment

Filter Cartridges

Fab-Tex Filtration manufactures a complete range of cartridge filters for dust collection and air pollution control systems. Filters are robust and reliable and can withstand the incredibly harsh environments often found in the food care industry.

Pleated Filters

Enjoy higher flow rates, longer life, and reduced maintenance costs with pleated filters. Fab-Tex quotes on direct replacements for an existing configuration or offers technical expertise to convert current bag filters over to PFEs.

Advanced Tandem Pleat Technology

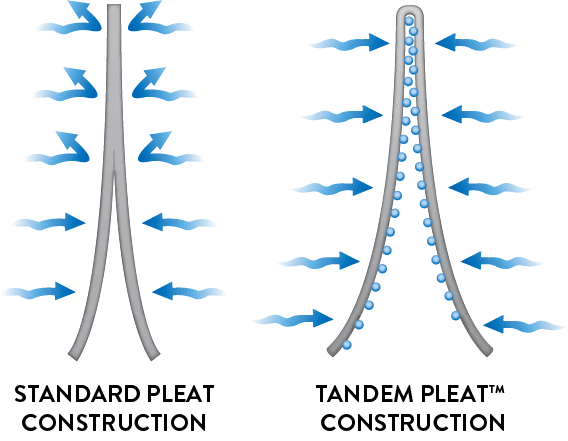

Upgrade to our innovative tandem pleat technology. Traditional filters can experience dead spots, where airflow is restricted because of outside air pressure forcing the pleat to collapse upon itself. Tandem pleat technology eliminates issues like these.

PTFE Membrane

Polytetrafluoroethylene (PTFE) is a microporous ‘skin’ applied to the surface of polyester filter media to provide extremely high filtration efficiency. This ‘non-stick’ surface increases dust release capabilities to improve reclamation of valuable dust. Discover the exceptional quality of Fab-Tex’s filter media, including our highly effective MERV 16-18 rated PTFE membrane.

View our catalogue for custom and standard competitive-fit filters

Reduce Contamination Risks and Protect Equipment with Air Filters

Implementing the following recommendations can greatly minimize the spread of bacteria in packaging equipment, food contact surfaces, and the product. Not only do air filters prevent contamination, but they also safeguard processing equipment against corrosion, extending the life of valuable machinery. By eliminating particles and dust from the air, the machines stay cleaner and operate at their best for longer.

Air Filtration Ratings

Food filters must be rated at a minimum efficiency of 99.999% at 0.01 micron to effectively reduce risk. They eliminate all remaining contamination and keep harmful bacteria out of packaged food products with this level of filtration.

Filtration Media

Get the right filter media and air-to-cloth ratio to prevent blockage when dealing with soluble powders like sugar, cocoa, and wheat. Choosing the correct dust collector is crucial; having too much filter media wastes money, while too little media can damage your system’s efficiency and equipment life.

Food-Grade Materials – Stainless Steel, Epoxy, and Silicone

Fab-Tex offers a range of tough, durable, and flexible materials specifically designed for the demanding food processing industry. Our options are formulated to ensure that any item that comes into contact with them remains unaffected.

Grade 304 or 316 Stainless Steel

Fab-Tex air filters and accessories are designed to meet strict disinfection and cleaning protocols. They are made from durable, food-grade stainless steel, which provides a corrosion-resistant and non-reactive surface. This is particularly important for applications with acidic filtrates, as other metals would react and potentially affect the taste or flavour of the product.

Epoxy

Food-grade epoxy adhesives are becoming extremely popular in the filter industry with more requests to keep production lines operational. Fab-Tex offers FDA-compliant adhesives and epoxies.

Silicone

In the food processing industry, it’s essential that the gasket doesn’t affect any items it comes into contact with. Choose specially formulated food grade silicone that won’t impact consumables. Silicone is the ideal material for FDA-approved gaskets and food grade seals as it offers elongation, a low compression set, and exceptional flexibility.

Industrial Air Filter Manufacturers

Fab-Tex Filtration has built an impressive reputation as an industry-leading filtration manufacturer in North America since 1995. For over two decades, we’ve been proudly providing the best air filters on the market to various professional entities – from small businesses to large ones.

Talk to an Air Filter Expert today for air filters tailored to your operation

Extend the filtration of capabilities of your dust containment and air pollution control equipment with Fab-Tex. Contact us about our custom manufacturing services and innovative new media.

Explore Fab-Tex Air Filter Solutions

Fab-Tex is dedicated to offering reliable air filter solutions to clients across a wide range of industries. Our high-quality air filters are ideal for commercial and industrial facilities, including: