The MERV rating (Minimum Efficiency Reporting Value) is a key metric for evaluating filter performance in commercial and industrial applications. In North America, the most widely accepted method for determining this rating is by using the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) 5.2.2 standard. The resulting rating reflects how effectively a filter traps and collects airborne particles to improve air quality.

The MERV rating (Minimum Efficiency Reporting Value) is a key metric for evaluating filter performance in commercial and industrial applications. In North America, the most widely accepted method for determining this rating is by using the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) 5.2.2 standard. The resulting rating reflects how effectively a filter traps and collects airborne particles to improve air quality.

Why MERV Ratings Matter for Industrial and Commercial Filtration

Filters installed in industrial and commercial filtration systems need to possess the right MERV rating for the application to preserve air quality and worker and equipment safety. Lower-MERV filters (e.g. MERV 4-8) will capture only coarse dust and lint, which might be sufficient to keep HVAC components (like coils and fans) from clogging. Many standard HVAC units are fitted with filters that have MERV ratings only high enough to protect the equipment from large dust, leaving people vulnerable. Such low-efficiency filters allow fine particles to bypass and recirculate, leading to poor indoor air quality and potential health risks for occupants. Higher-MERV filters (MERV 13+) can trap much finer particles including mold spores, aerosolized oil mists, welding fumes, and even some bacteria. This leads to cleaner air that safeguards worker respiratory health, protects sensitive products (in food or pharma production), and reduces dust settling on surfaces or finished goods.

MERV Rating Chart

When you need to compare filter options from different suppliers, a MERV rating chart can come in handy. Being the standard for measuring and reporting air filter efficiency, MERV ratings help you select the right product for your operation. Fab-Tex supplies air filters for industrial dust collectors and air pollution control uses.

Efficiency Reporting Value (MERV) |

|||

|---|---|---|---|

19 - ULPA 18 - HEPA 17- HEPA |

Pharmaceutical Manufacturing Radioactive materials Clean rooms/ Lab Settings |

< 0.30 pm particle size (Small), Viruses, carbon dust, combustion smoke | 99.7% or better on less than 0.30-micron particle size ● HEPA Filter Media ● Final Stage Filters ● Bag & Box Filters |

15 14 13 |

Superior Commercial Buildings Welding fumes Surgery/Hospital Inpatient Care Smoking Lounges |

.3 -1.0 pm Particle Size (Small) All Bacteria, smoke, sneezes, plasma and laser cutting, food manufacturing, welding fumes |

95% or better on 0.3–1.0 micron particle size ● Nanofiber Media Cartridges ● PTFE Coated Media Filters ● Cartridge Filters |

11 10 9 |

Manufacturing Facilities Better Commercial Buildings General Nuisance Dust Food Processing |

1.0-3.0 pm Particle Size (Medium) Coal dust, lead dust, wood dust, fibrous dust, legionella, humidifier dust, milled flour, auto emissions |

85% or better on 1.0–3.0 micron particle size ● Spun Bond Polyester Media ● 80/20 Cell/Poly Blend Media ● Cartridge Filters ● Bag Filters |

7 6 5 |

Good Commercial Buildings General Nuisance Dust Industrial Workplace Paint Booth Inlet |

3.0-10.0 pm Particle Size (Large) Dust mites, pollen, sanding dust, spray paint dust, textile fibers, carpet fibers, dusting aids, and cement dust |

Less than 80% on 3–10 micron particle size ● Cellulose Media ● Pleated Filters ● Cartridge Filters ● Throwaway Filters |

3 2 1 |

Minimal Filtration Residential Furnace Window/AC Units |

>10.0 pm Particle Size (Large) Dust mites, pollen, sanding dust, spray paint dust, textile fibers, carpet fibers |

Less than 20% on 3-10 micron particle size ● Throwaway Filters ● Washable Filters ● Electrostatic Filters |

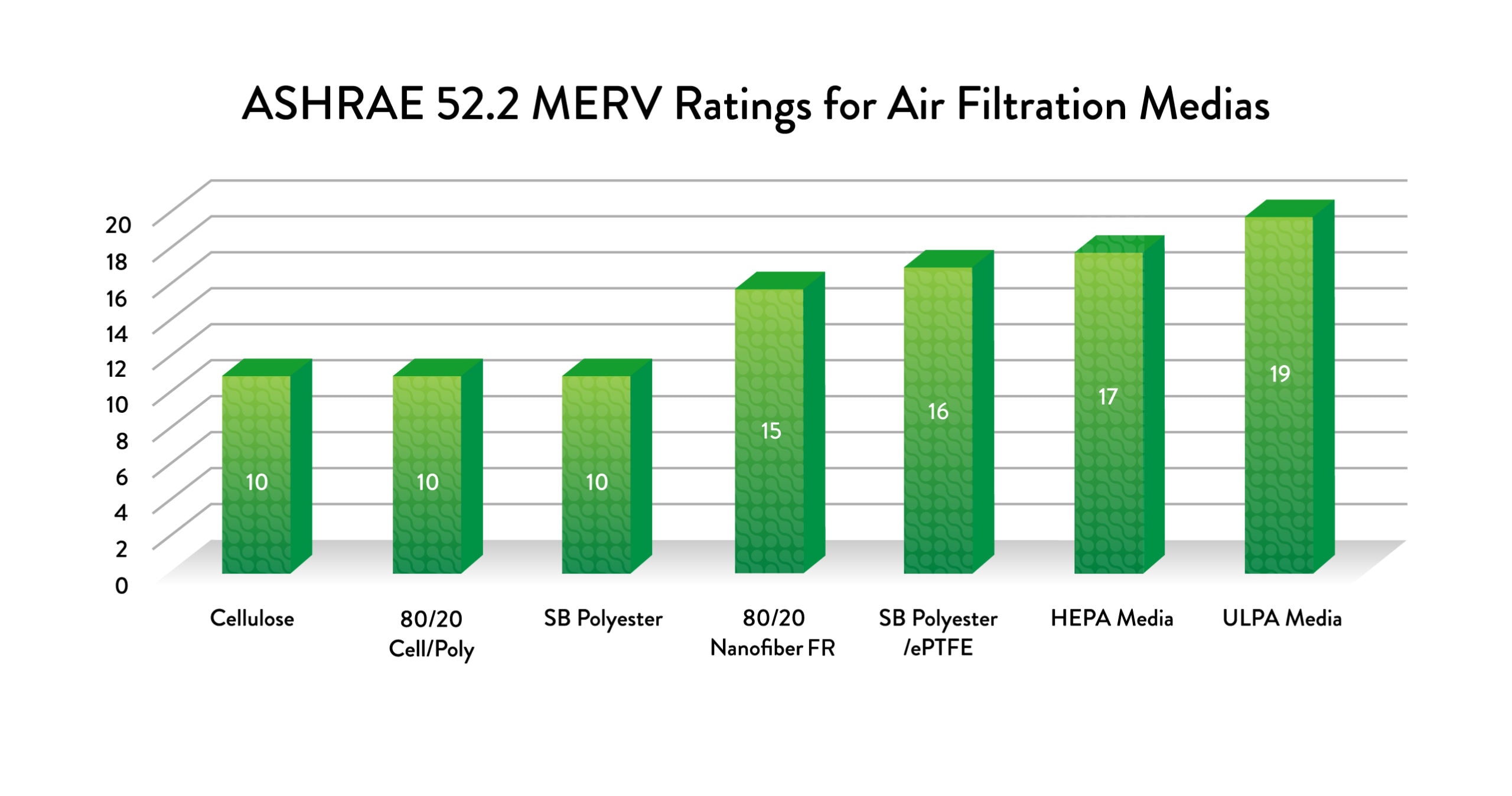

MERV Ratings for Air Filtration Medias

MERV Ratings for commonly used filter medias are as follows:

- 100% Cellulose Media – MERV 10: 50% – 65% efficiency on particulate in the 1-3 micron range.

- Spunbonded Polyester – MERV 10: Greater than 80% efficiency on particulate in the 1-3 micron range.

- 80/20 Cellulose/Polyester – MERV 11: 65% – 80% efficiency on particulate in the 1-3 micron range.

- 80/20 Cellulose/Polyester with Nanofiber Membrane – MERV 15: Greater than 90% efficiency on particulate in the 1-3 micron range and 85% – 95% efficiency in the .3 – 1 micron range.

- Spunbonded Polyester with PTFE Membrane – MERV 16: Greater than 95% efficiency on particulate in the 1-3 micron range and greater than 95% in the .3 – 1 micron range.

- HEPA Medias – MERV 17: 99.97% efficiency on .3 micron particulate.

- ULPA Medias – MERV 19: 99.99999% efficiency on .3 micron particulate.

Canadian Standards and Environmental Considerations

MERV ratings also matter in regulatory compliance and safety. Many jurisdictions set standards or guidelines for air filtration in workplaces. Canadian building guidelines often recommend at least MERV-8 filtration in basic areas for equipment protection, and MERV-13 in occupied areas to maintain healthy air. A higher MERV rating can help facilities meet indoor air quality standards and occupational exposure limits by filtering out hazardous fine dust and fumes before air is recirculated or exhausted. In processes that generate dangerous particulates (e.g. welding with hexavalent chromium or combustible dust), using filters with an appropriate MERV rating is part of a comprehensive safety strategy.

MERV ratings also matter in regulatory compliance and safety. Many jurisdictions set standards or guidelines for air filtration in workplaces. Canadian building guidelines often recommend at least MERV-8 filtration in basic areas for equipment protection, and MERV-13 in occupied areas to maintain healthy air. A higher MERV rating can help facilities meet indoor air quality standards and occupational exposure limits by filtering out hazardous fine dust and fumes before air is recirculated or exhausted. In processes that generate dangerous particulates (e.g. welding with hexavalent chromium or combustible dust), using filters with an appropriate MERV rating is part of a comprehensive safety strategy.

In Canada, cold winters and seasonal air quality issues make high-efficiency filtration essential. Many facilities recirculate heated air to conserve energy, requiring filters with adequate MERV ratings to remove contaminants like fine dust during recirculation. Outdoor factors such as wildfire smoke and pollen also call for stronger intake filters (likely MERV-13 or higher) when conditions worsen. Filter choices should also account for local regulations, as some industries (like food and pharma) require higher air cleanliness standards.

MERV Filter Ratings and Filtration System Efficiency

A high MERV rating doesn’t automatically mean the filter is better for a given application. Filters with higher MERV ratings tend to restrict airflow because they have smaller pores to capture smaller particles. If such filters are used with a system not designed to handle the higher resistance, it creates strain, lowering the system’s overall efficiency.

Not sure what’s the best MERV rating for filters in your system? Speak to a Fab-Tex Filter Expert Today!

How to Determine MERV Ratings

To calculate a filter’s MERV rating, six dust loads containing particles between 0.3 and 10 microns are passed through the media. This process measures the filter’s ability to capture particles across various size ranges. Higher MERV ratings indicate better performance in removing smaller, sub-micron particles.

It’s important to note that the MERV rating reflects the filter’s minimum tested efficiency. In actual use, once the filter media becomes coated with particulate, its efficiency typically improves, often performing better than the test results suggest.

Understanding the Limits of MERV Testing

MERV ratings are determined through standardized testing on the filter media itself, not the fully assembled filter. Overall filter performance in real-world conditions may vary based on the final design and construction of the complete filter unit.

The filter’s MERV rating is just the start! Find Your Complete Filter Solution with Fab-Tex

MERV ratings are important, but real filtration performance goes beyond the numbers. Fab-Tex designs and manufactures custom OEM-equivalent filters tailored to your application, offering specialized media, custom pleat designs, and durable components.

Explore how our in-house capabilities deliver high-performance solutions built to last.

Selecting the Proper Industrial Air Filter

Advancements in filter media, materials, and overall design and construction (including Fab-Tex’s Tandem Pleat Technology for high-efficiency filters) have led to an explosion of high-performance filters. Fab-Tex works with customers across numerous industrial environments, all of which rely on industrial air filters:

● Critical food applications

● Welding shops

● Manufacturing environments

● Powder Coating facilities

● Pharmaceutical applications

● Woodworking industries

● Environmental Service Providers

And anywhere else, dust containment equipment is present!

Filters manufactured by Fab-Tex filters offer the best in efficiency, performance and expected life cycle.